Articles

HVAC Contractor Tips and Articles For Your Home

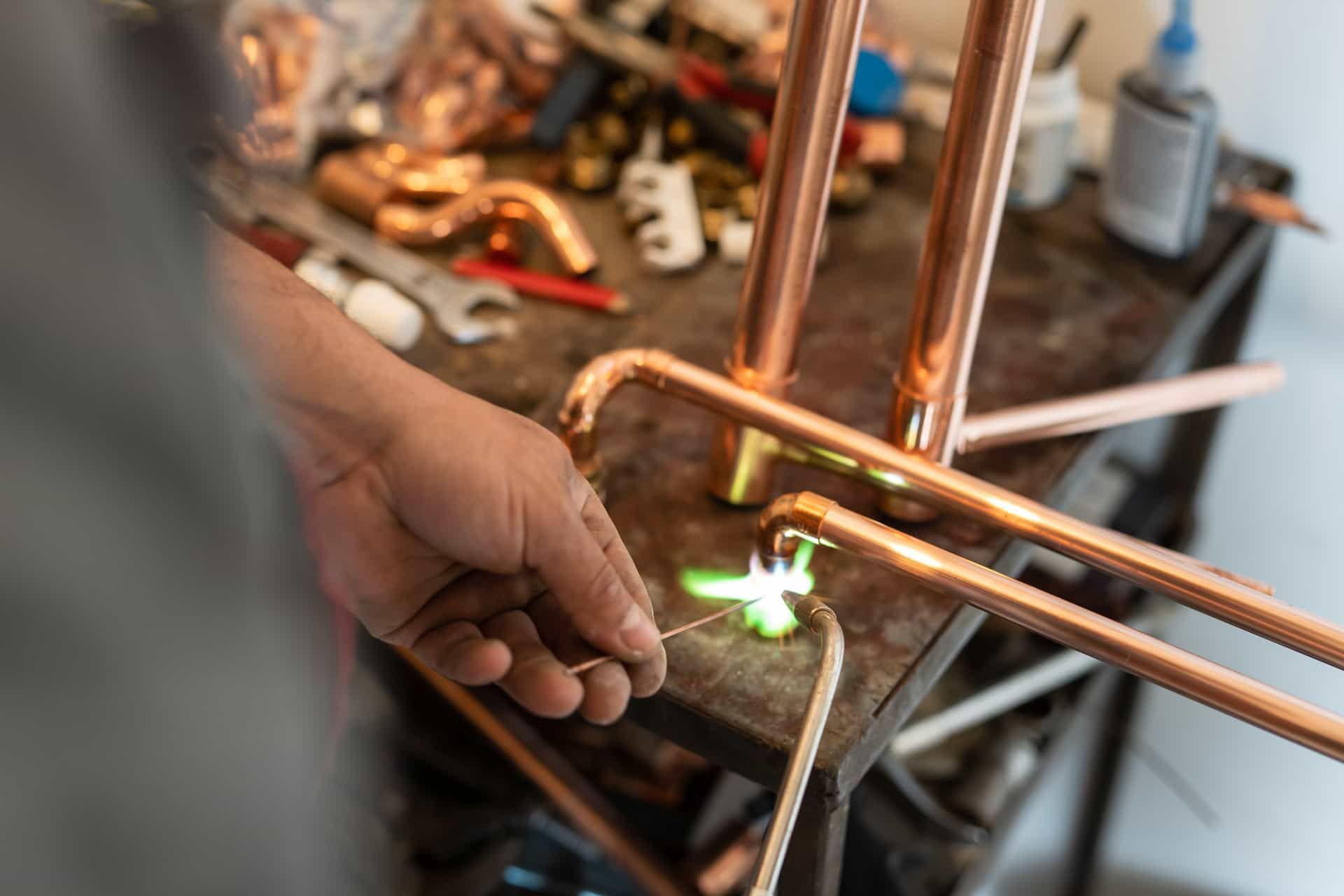

Can Plumbing Solder Be Used for Electronics?

Soldering is an essential process in both plumbing and electronics, but not all solders are the same. If you’ve ever wondered whether plumbing solder can be used for electronic work, the short answer is no—and there are good reasons why.

Using the wrong type of solder can cause serious problems, including damage to electrical components and potential safety hazards. In this article, we’ll explore the key differences between plumbing and electronics solder, why they are not interchangeable, and the best type of solder for electronic projects.

Understanding Solder and Its Purpose

Solder is a metal alloy that is melted and used to join two materials together. It is commonly used in two fields:

- Plumbing: To connect metal pipes and fittings, ensuring a leak-proof seal.

- Electronics: To join electrical components, such as wires and circuit boards, creating a reliable electrical connection.

Although both types of solder serve a similar function, their composition and properties differ significantly, making each suited for its intended application.

The Key Differences Between Plumbing and Electronics Solder

1. Material Composition

The most important difference between plumbing and electronics solder is their composition.

- Plumbing Solder: Traditionally contains lead or lead-free alternatives like tin, silver, and copper. It often includes acid-based flux, which helps clean the pipe’s surface for a strong joint.

- Electronics Solder: Usually made of tin and lead or lead-free alloys like tin and silver. It uses rosin-based flux, which is non-corrosive and safe for delicate electronic parts.

2. Flux Type

Flux is a chemical agent in solder that removes oxidation and improves the bond.

- Plumbing Solder Flux: Acid-based flux aggressively removes oxidation from metal pipes, ensuring a watertight seal. However, this flux is highly corrosive and can damage electronic components if used incorrectly.

- Electronics Solder Flux: Rosin-based flux is specifically designed for electrical connections. It is non-corrosive and does not damage delicate circuitry.

3. Melting Temperature

Plumbing solder typically requires higher melting temperatures than electronics solder:

- Plumbing Solder: Generally melts between 360°F and 460°F (182°C - 238°C), requiring a propane torch or high-powered soldering tool.

- Electronics Solder: Melts at a lower temperature, around 370°F (188°C) for lead-based solder and slightly higher for lead-free versions, making it easier to work with using a standard soldering iron.

4. Application and Strength

- Plumbing Solder: Designed for durability and leak-proof seals, making it strong enough to withstand high water pressure and temperature fluctuations.

- Electronics Solder: Creates electrical connections that allow the flow of electricity. It must be conductive and non-corrosive to prevent damage to circuits.

Why You Should NOT Use Plumbing Solder for Electronics

1. Corrosive Acid Flux Can Damage Electronics

One of the biggest reasons plumbing solder should never be used for electronics is its acid-based flux. When applied to electronic components, this flux can:

- Corrode metal connections, leading to circuit failure.

- Leave behind residue that can short out electrical components.

- Reduce the lifespan of your electronic devices.

2. Higher Melting Temperature Can Overheat Components

Plumbing solder requires more heat to melt than electronics solder. Using a high-temperature torch or powerful soldering tool can:

- Burn delicate electronic components like resistors and transistors.

- Melt plastic parts found in circuit boards.

- Cause poor connections, making the circuit unreliable.

3. Lead Content and Health Hazards

Older plumbing solder often contains lead, which is toxic. While lead-based electronics solder exists, it has a much lower lead content designed for safe electrical applications. Using plumbing solder in electronics increases the risk of lead exposure, which can be harmful to both your health and the environment.

Current regulations prohibit the use of lead-containing solders in potable water systems and water treatment due to health risks associated with lead exposure..

The Right Type of Solder for Electronics

If plumbing solder is not suitable for electronics, what should you use instead?

1. Lead-Based Electronics Solder

- Composition: 60% tin, 40% lead (Sn60Pb40)

- Melting Point: 370°F (188°C)

- Features: Easy to work with, reliable connections, good conductivity

- Best for: General electronics repairs and circuit board soldering

2. Lead-Free Electronics Solder

- Composition: Tin, silver, and copper (Sn96.5Ag3.0Cu0.5)

- Melting Point: 420°F (215°C)

- Features: Environmentally friendly; slightly harder to work with

- Best for: Eco-friendly applications; industries requiring RoHS compliance

3. Silver-Bearing Solder

- Composition: Tin and silver

- Features: Higher strength and reliability; great for sensitive electronics

- Best for: High-performance applications; aerospace; medical devices

How to Properly Solder Electronics

Using the right solder is just one part of the process. Here’s how to properly solder electronic components:

Step 1: Gather Your Tools

- Soldering iron (15-60W)

- Electronics solder (rosin-core, lead-based, or lead-free)

- Sponge or brass tip cleaner

- Heat-resistant mat

- Desoldering pump or wick (for mistakes)

Step 2: Prepare the Components

Ensure the components and wires are clean and free of oxidation. Secure the parts in place with helping hands or a vise.

Step 3: Heat the Connection, Not the Solder

Touch the soldering iron tip to the joint for a few seconds. Apply the solder to the heated joint—not directly to the iron—and allow it to flow smoothly over the joint evenly.

Step 4: Inspect and Test

The solder joint should be shiny and smooth. Avoid excess solder as it can create short circuits. Use a multimeter to check for proper connections.

Final Thoughts

Plumbing solder and electronics solder are designed for different applications and should not be used interchangeably. Plumbing solder contains acid-based flux that can corrode electrical components, requires higher temperatures that may damage sensitive parts, and lacks conductivity needed for electronic circuits. For electronic work, always choose rosin-core electronics solder to ensure safe, reliable connections.

Need help with electrical or HVAC repairs? Contact

Gleason Heating and Air Conditioning today for expert service!

Disclaimer: The information on this website and blog is for general informational purposes only and is not professional advice. We make no guarantees of accuracy or completeness. We disclaim all liability for errors, omissions, or reliance on this content. Always consult a qualified professional for specific guidance.

Recent Posts

Contact Us

Contact Us

We will get back to you as soon as possible.

Please try again later.

CALL US TODAY

OUR OFFICE

1246 Karl Ct Wauconda, IL 60084

What Makes Gleason Different

Our main advantages! See what makes Gleason stand out from the competition

Find Your Service Area

Gleason Service Areas

Since 1950, Gleason Heating and Air Conditioning has proudly served a wide range of communities throughout northern Illinois. Whether your air ducts need cleaning in Mundelein, or your furnace in Wauconda is on the fritz, it’s our mission to help you regain your home comfort as soon as possible.

For complete plumbing, heating, and cooling services near you in Illinois, contact Gleason's HVAC system experts! Not sure if our team services your area? Give us a call today and find out how we can help!

If you don't see your area listed below, please give us a call on

Our HVAC contractor experts are here to provide you with superb service for your Wauconda area home.

24/7 Emergency Service Available

All Rights Reserved.

Website Designed & Managed by Oamii.